A project I wanted to do required me to roll some steel rings from round rod of varying thicknesses and diameters. I looked at commercial rolling tools and even the cheapest ones, such as the offerings of Harbor Freight, were $80. But they didn’t have exceptional reviews and they would mar 1/4″ rod, something that wouldn’t be tolerated for the art piece I was going to build. So, I decided to build my own.

I had seen several designs online that utilized an ordinary vice, which would cut down on design complexity and cost. I went to work on my own such design, sourcing off-the-shelf components that would be most suitable for the job. Here is the design I came up with:

The primary components here are:

- Two 1.5″ x 1.5″ x 0.125″ angle irons, 4″ long each

- Two McGill CFH1 1/4 cam followers ($6.35 each on sale, Amazon)

- One sheave (pulley) 685 lb load capacity, item 5RRX9 from Grainger. ($6.58)

The cam followers have a 0.75″ stud, so I picked-up the appropriate hardware for them locally. There is also a steel arm (1/8″ x ~1″ flat bar) attached to the pulley using two 1/4″ grade-8 bolts, which I tapped holes in the pulley to accept. The who thing simply bolts to the two inside faces of the vice.

Some of the pieces:

The finished unit:

Being put to work:

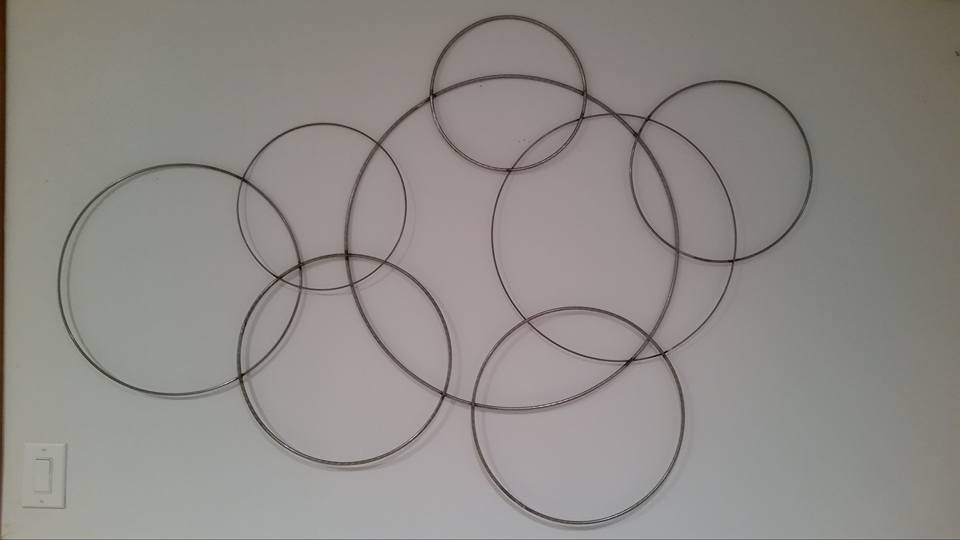

The completed art project. For scale, the largest circle is 2 feet diameter, 1/4″ rod. I also used 3/16″ and 1/8″ rod for contrast.

As for rolling tips, the first step is to clean the oil of the rod. Mineral spirits worked well for me. When rolling, don’t try to achieve the final radius in a single pass. I found 2 to 3 passes worked well depending on how tight of a radius I wanted and the thickness of the rod I was rolling. Oil on the rod or trying to do too much of a bend at once may/will cause the pulley to slip.