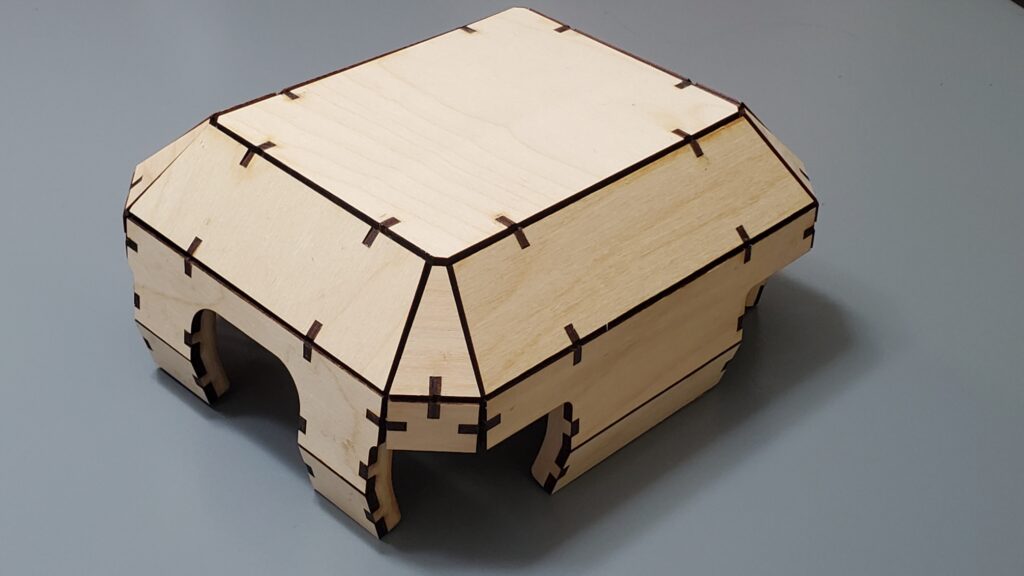

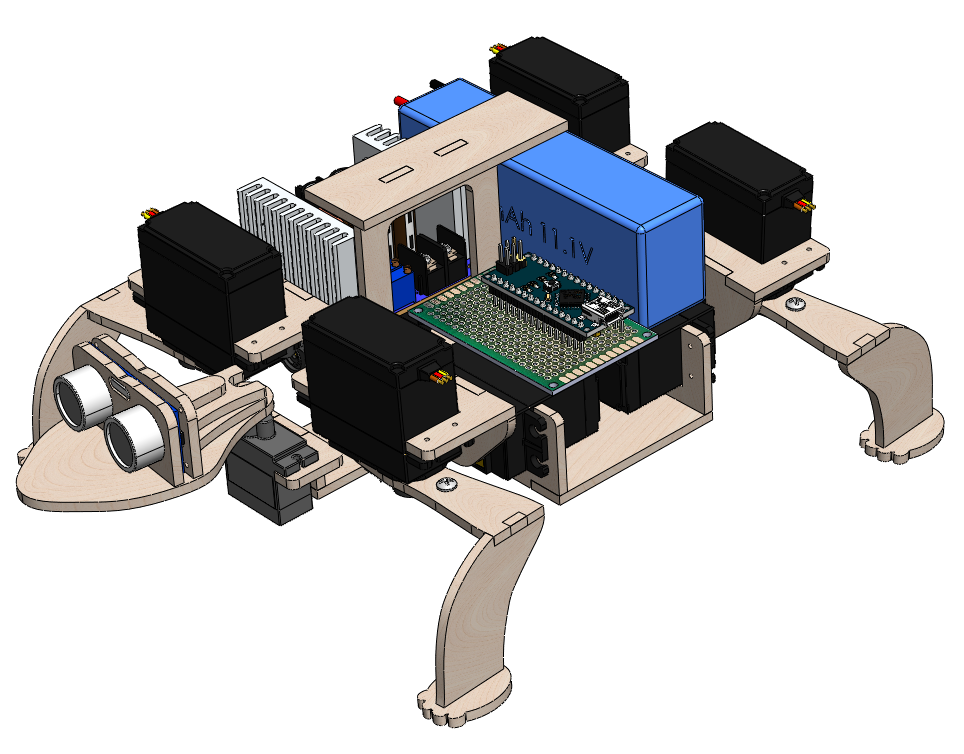

It’s time to go BIG! The robotic tortoise is getting super-sized and will use full-size servos instead of the micro servos. It will be getting a “head” with an ultrasonic sensor for depth perception. This should be a fun one! I’ll continue to update this post as this phase of the project progresses.

1/29/2023 – Design Progress

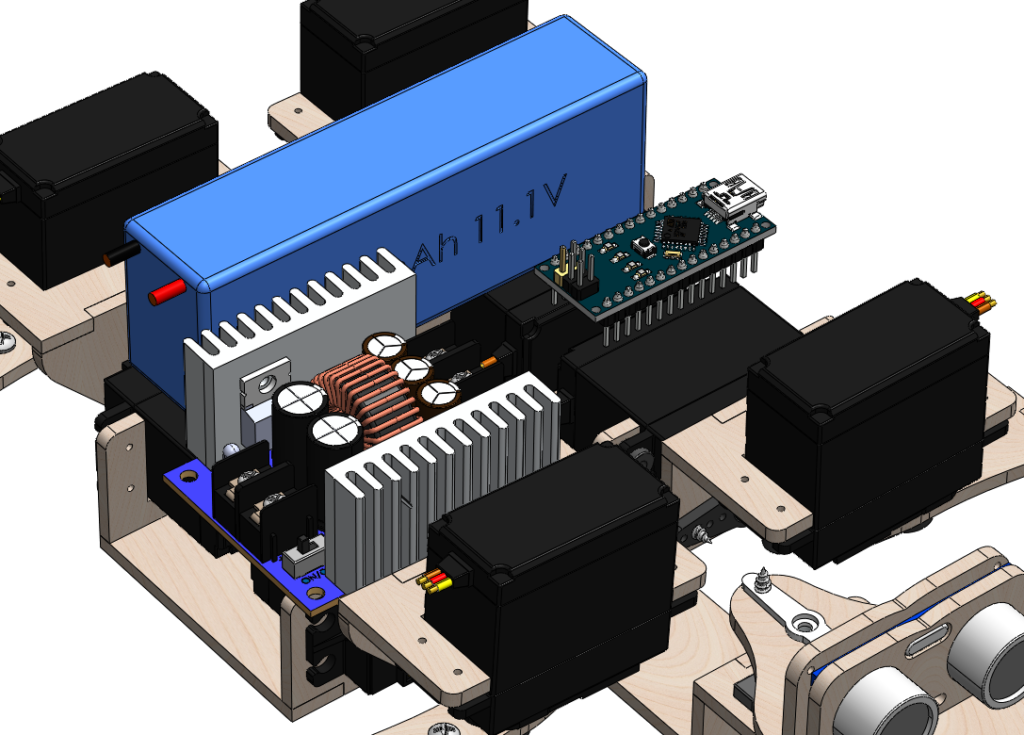

Over the last two days I’ve been working on the CAD model for the design. It’s mostly designed at this point, with a few items to be tweaked later.

Similar to the small prototype, this one will also utilize 8 servos (MG 996R), two per leg. These will be run at 6V, using a 3S (11.1V LiPo battery), with a power step-down regulator (SZBK07) that can handle up to 20amps. The “brain” will be an Arduino Nano mounted to a custom (to be built) circuit board. A 9th servo will be used for rotating the head. For that I’ll use a small MG90 servo. The body will be made entirely of 1/8″ birch plywood and I’ll again laser cut the components. A turtle shell is being planned for as well.

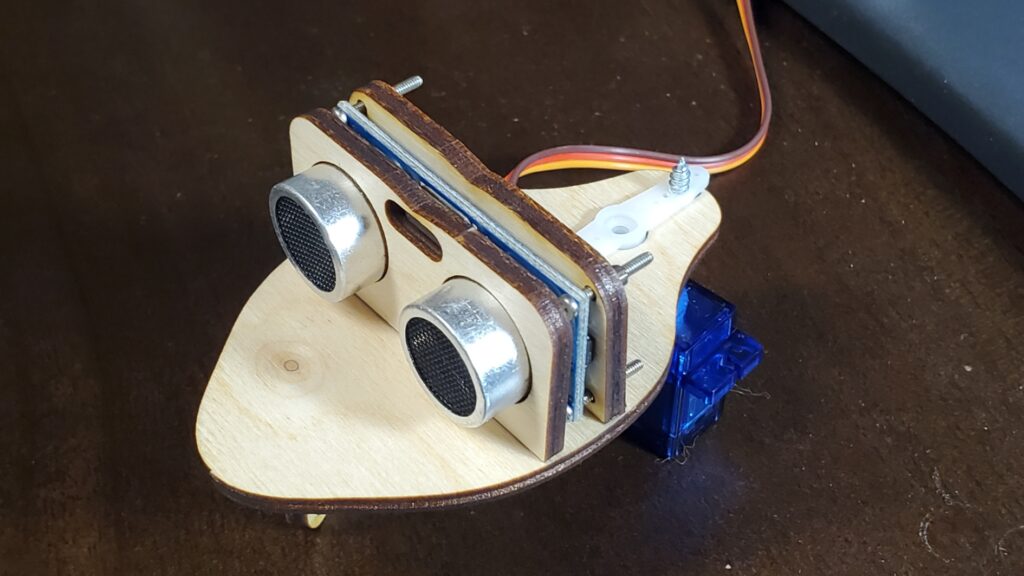

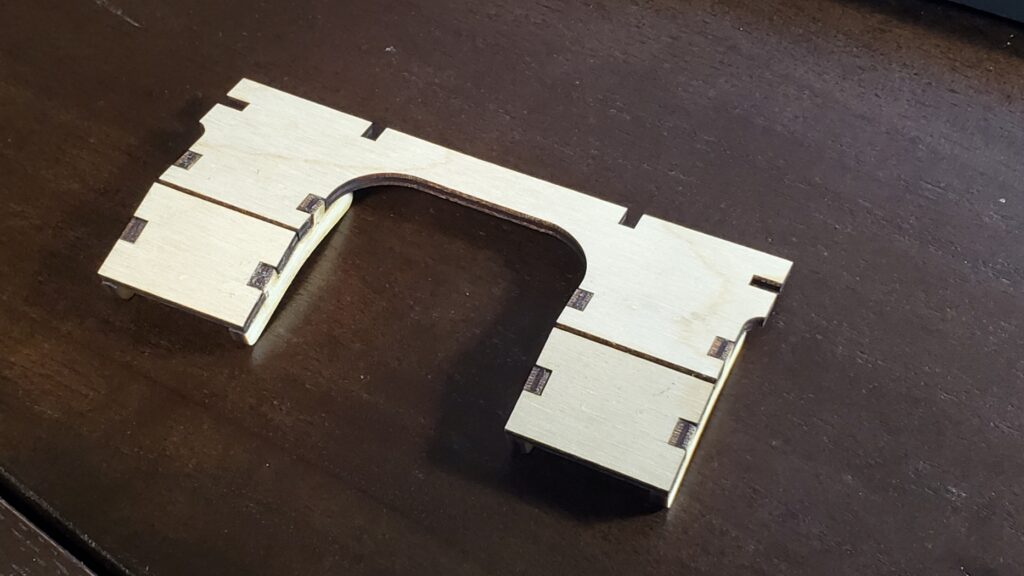

Today I also did a test cutout of the head pieces. I discovered some hole alignment issues with the vertical wooden component that mounts the ultrasonic sensor. The error was traced back to some incorrectly spaced holes on the model I downloaded from GrabCAD. I re-measured the circuit board mounting holes, updated the model and re-cut. Perfect!

I’ve also roughed-out the placement of some of the main electrical components, including power regular, LiPo battery and Arduino. I’ll probably be adding a built-in tray to mount all those to, that is one of the items still to be figured out.

1/30/2023 – Battery Monitor

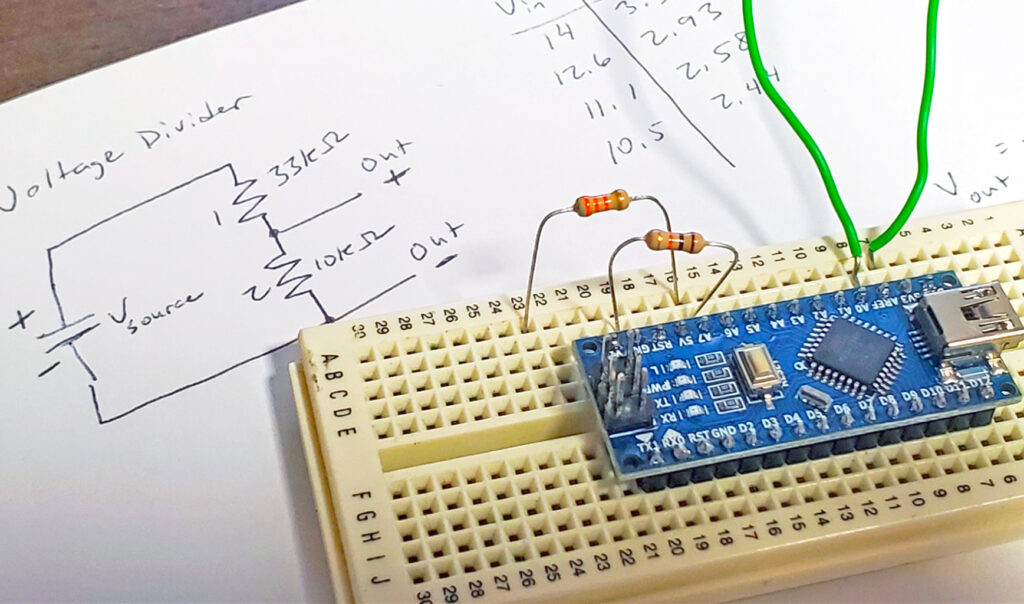

The tortoise will be powered using a 3S 11.1V LiPo battery. Fully charged, the cells are balanced charged to 4.2V each, or 12.6V total. I want to monitor this voltage and have a low-voltage threshold of 11.1V, or about 3.7V per cell. I do not wish to monitor each cell individually, nor is such precision needed in this application. While some cells may drop below 3.7V, they should still remain well above the absolute minimum voltage for LiPo cells of 3.0V.

To measure the voltage, I’ll have a battery wire run to an analog pin on the Arduino. The Arduino Nano I’m using has a maximum input voltage of 5V on the analog pins. Further, since I’ll be using 3.3V as a “reference voltage”, I need to cap my input voltage at 3.3V. To do that, I will scale the battery voltage using a voltage divider circuit. That will keep the voltage within the range of 0-3.3V. I will design in a margin of error, with the divider circuit being able to accept a maximum voltage of 14V, which scales down to roughly 3.3V using the circuit shown below.

The actual voltage operating range will be 11.1V to 12.6V, which scales to 2.58V and 2.93V, respectively.

// Test program to read battery voltage using analog input pin.

// Program sets AREF to utilize EXTERNAL voltage reference, 3.3V in this case.

void setup() {

Serial.begin(9600);

analogReference(EXTERNAL);

}

void loop() {

// read input on analog pin A7

int sensorValue = analogRead(A7);

// Convert the analog reading (which goes from 0 - 1023) to a voltage (0 - 3.3V):

float voltage = sensorValue * (3.3 / 1024.0); // 1024 discrete steps from 0-1023

voltage = voltage / 0.2326; // adjust display voltage to show input voltage

Serial.println(voltage); // display voltage

delay(100);

}2/16/2023 – Preliminary Design Completed

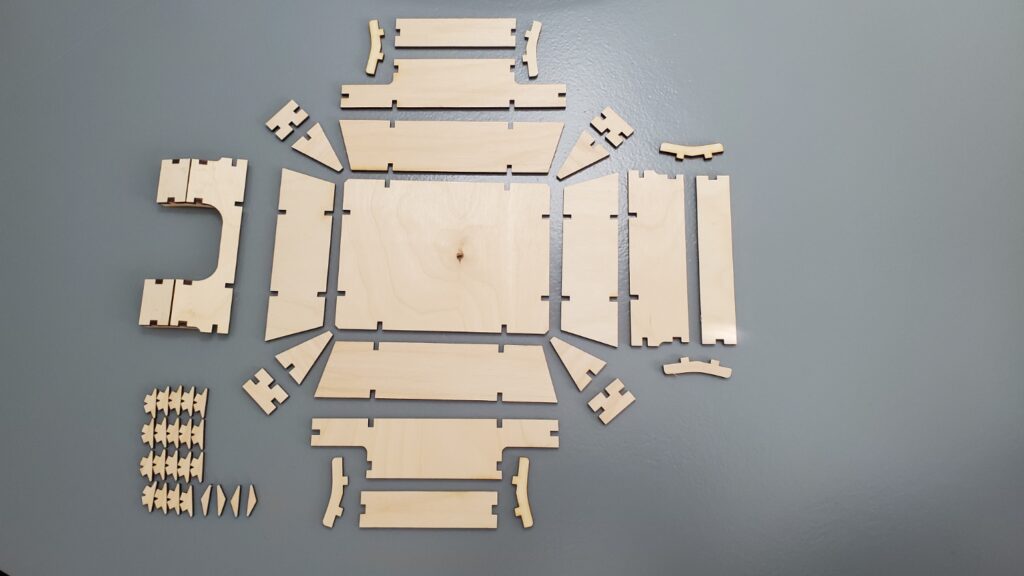

Over the last couple of weeks as time has permitted, I’ve been able to finish the preliminary design, including a faceted turtle shell.

The moveable head has been refined and I’ve implemented a simple attachment structure for the shell, which will either utilize hook-and-loop or magnets as the fastening mechanism.

I completed a small portion of the turtle shell to validate the general design. The pieces assembled very easily and fitment was as expected.

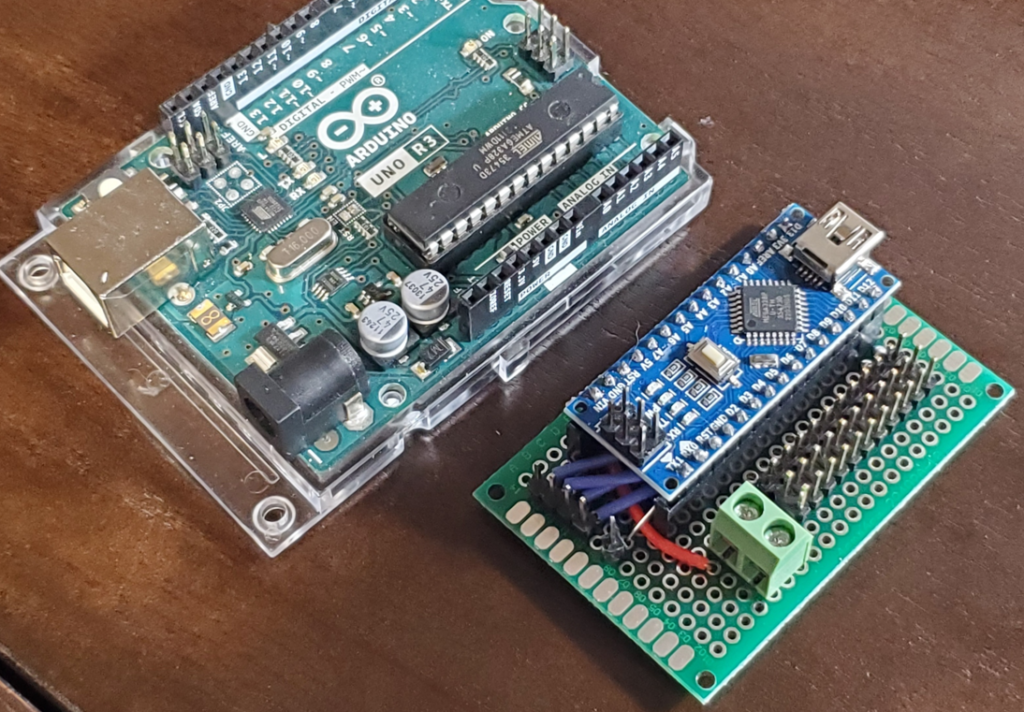

I’ve also completed the new “turtle brain”. On the prototype tortoise, I had utilized an Arduino Uno and made a shield for it. It worked, but was a bit bulky. This time, I’m using an Arduino Nano and a much smaller circuit board to accomplish the same thing, and more! Features:

- Header pins for connection of 8 leg servos and 1 head servo

- Header pins for ultrasonic sensor

- Single header pin for measuring battery voltage (voltage monitor via analog to digital converter)

- Voltage divider circuit for reducing battery voltage from 14v to 3.3v (approx.)

- Terminals for connecting to power supply

2/20/2023 – Shell complete

After cutting somewhere around 50 pieces and assembling them all, the turtle shell is complete! The shell went together pretty well overall, however, I did identify some areas that could be tweaked to help better facilitate assembly and provide better alignment/indexing. I assembled each side separately, then put them together using the corner pieces. Due to slight misalignment throughout, the tolerance stack-up was noticeable. Overall though, I’m again very pleased with the final shell!

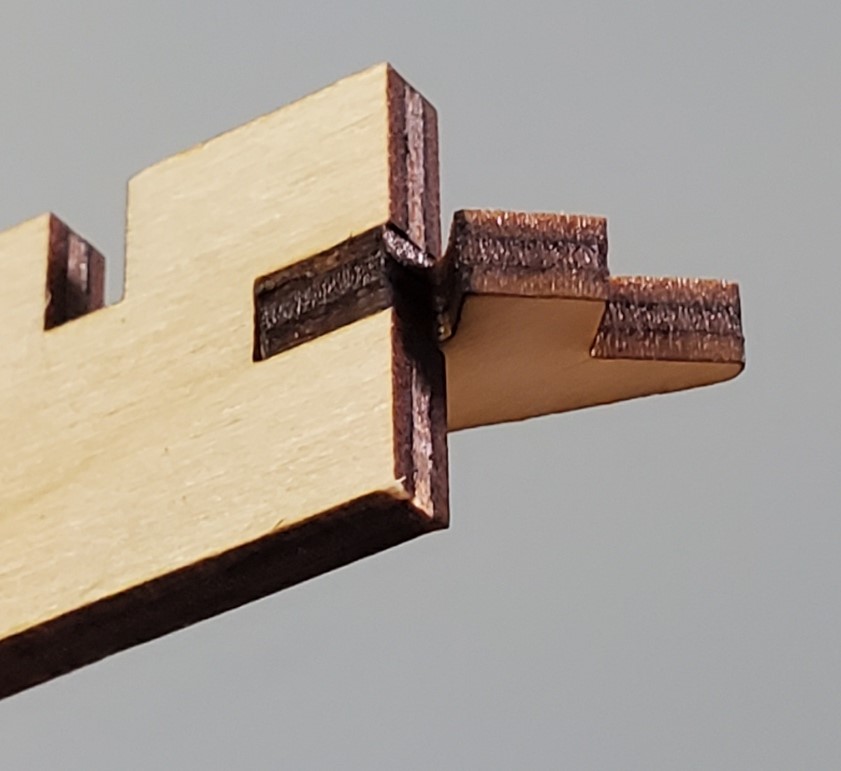

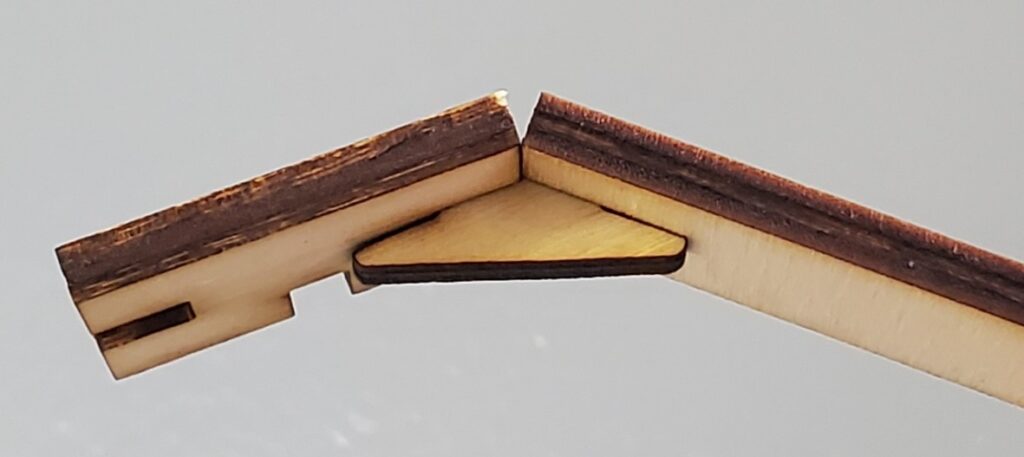

I designed the joining pieces so that they would be mostly unseen from the outside. You can see how that worked below:

More assembly: